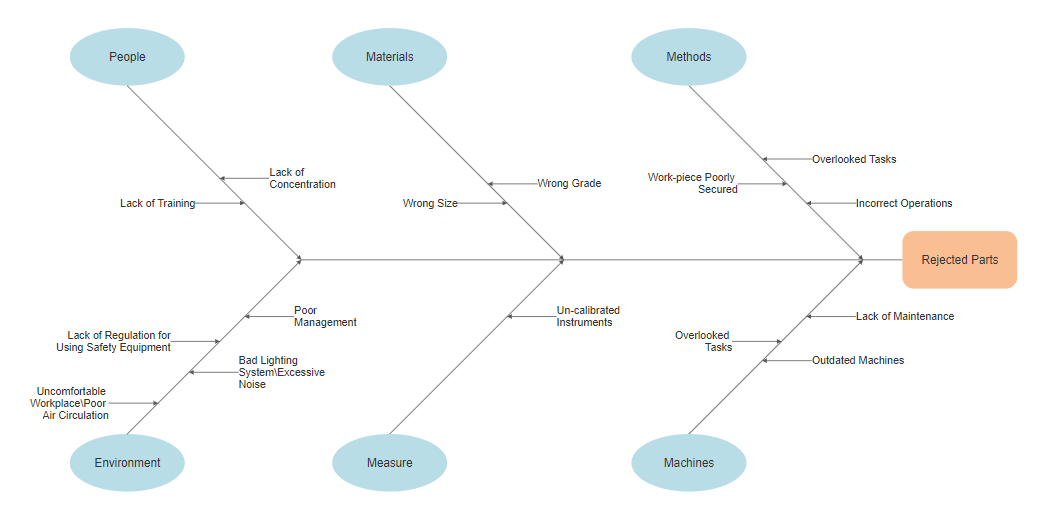

The causes are divided into six main branches in manufacturing, which are collectively referred to as the 6 Ms of manufacturing. After that, you need to give bones to the fish. Later, you can add effect to the diagram, once you agree on the effect. Whether it is manufacturing or any other area, the first thing you should do is to clearly know the effect or outcome of the analysis. Using the Fishbone Diagram in Manufacturing This diagram can be used in manufacturing, sales process and marketing. Pioneered by Kaoru Ishikawa, he introduced this diagram at Kawasaki for the quality management processes. This diagram determines the possible causes of a specific event or problem. When you want to display the sequence of related factors.When you present the incidence of certain elements.When you want to reveal the important relationships among variables and possible causes.When you want to get additional insight into the process behaviors.When you want to see the relationship of various factors contributing to a problem.When you want to demonstrate and organize several theories as to what the root causes of the problem would be.When you want to focus the team on the causes rather than the problem or issue.When you want to focus the team on the causes instead of symptoms.Here’s is when you can use the fishbone diagram. One of the best and effective ways to sort these ideas and arouse the teaMs brainstorming in order to know the root cause is the fishbone diagram. The fishbone diagram is used when you want to determine the major cause or root cause of the problem. Our ready-made samples and examples help users get started as fast as lighting. You can use any of them for resolving your issues and understanding the effects. There are several fishbone diagram templates available on our main website. These elements and causes mentioned above are categorized separately in the fishbone diagram. Materials: These are the parts, raw materials, paper, pen that is used to produce the final product.Environment: These are the conditions, time, location, temperature, and culture in which the process operates.Measurements: This is the data that is generated from the process used to evaluate its quality.Machines: These are the computers, tools, and equipments that are used to fulfill the task and job.People: They are the ones who are involved in the process.Methods: This section covers the details of the process and some specific requirements for doing it, such as procedures, rules, policies, regulations and laws.As mentioned above, the causes are grouped into key categories so as to be able to recognize sources and causes for any variations.

Typically, the Ishikawa diagram is used to determine factors that could potentially lead to a major, overall effect, particularly in quality defect prevention and product design processes. The first one is the primary cause that could directly lead to the effect while the secondary cause is the one that could lead it to a primary cause which does directly does not have an end effect. Generally, this fishbone diagram is used to present causality and it has two causes, primary and secondary cause. Moreover, analysts can see the real time snap-shot of the collective inputs of the team.

Also, it lets you focus on the symptoms or history of the problem. Once the problem is found, they eliminate them which enable the team to focus on why the problem has occurred. The core aim of this diagram is to brainstorm all the potential causes that could cause the difficulty and then go deep inside the factors that are causing the problem eventually. Owing to the popularity and applications of the process, he soon became the founding fathers of modern management. He introduced this diagram for the quality management process in the Kawasaki shipyards. This diagram was first introduced by Kaoru Ishikawa in 1968 this is why it is also called as Ishikawa diagram. Basically, there are various causes grouped into several categories highlighting the causes of the potential issue. It is a simple tool that is used for brainstorming issues and reasons of particular problems. It is also called as Ishikawa diagram and cause and effect diagram. The fishbone diagram is a very simple tool that permits effective and quick root causes in the pursuit of corrective actions.

0 kommentar(er)

0 kommentar(er)